Factory Capacity

KP production plants are capable of satisfying large volume orders of CE and FDA certified protective face masks.

Masks Delivered Everyday

Cleanroom for Production

Laboratory for Stringent Testing

Working around the Clock

100,000 Class Dust Free Factory Plants

Incorporating 3000 square meters of a sanitized area in our production floor significantly minimizes the number of contaminants to our finished product. Every worker must follow our strict decontamination procedures before they enter the space. We ensure all of our packaged face masks are safe to wear thanks to our dust-free production area.

Mask Manufacturing Processes

Learn how surgical masks are made in our factory.

Raw Material Inspection

Sourcing from reliable suppliers, we conduct extra inspectoin on all raw materials for making masks before we set and commission the machine. Main materials for producing masks include:

- Non-woven fabric of 20 or 25 gsm (PP)

- Meltblown fabric of 20 or 25 gsm(MB)

- Metal Nose clip

- Earloops

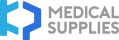

Automatic Forming

We use automatic machines to finish the main body of a mask. By setting on materials needed and configurating neccesary parameters, the machine will proceed to deliver masks at a pace of 80 pieces/min.

- Ultrasonic Laminating

- Ultrasonic Bonding

- Fabric Slitting

- Cartilage Bridge Joining

- Die Cutting

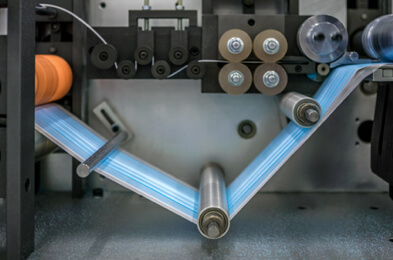

Earloop Joining

This process makes a final step of finishing a mask. Using a welding machine, the earloop will be be adhered to the masks. The finished earloop must stand the tensile force of 10N.

- Welding by manual/machine

- Sewing by manual/machine

Inspecting

During the automatic manufacturing process, the machine helps to weed out the defective ones. Besides, our workers monitoring the production processes will take an eye on the finished products. Any defect being spoted will be immediately removed from the production line.

- Black dusts

- Holes

- Loose earloops

Packaging

When the masks are finished and tested qualified, we put them into pp bags that have been sterilized. For medical masks requiring sterilization, they will be sent to EO sterilizers for EO resolution after the packaging process. The way of packaging include:

- Individual package

- 10 pieces per pack

- 50 pieces per pack

- Printed packaging boxes

In-House Lab for Quality Tests

KP set aside a sizable investment to our in-house laboratory for advanced diagnosis instruments and research machinery. The tools allow us to develop face masks with superior protective qualities while having eco-friendly properties, helping you stand out among other distributors in your target market.

Experts Team

We regularly consult local and foreign professionals of the industry, which is made possible through our connections with academic research establishments and industrial organizations. We also hire engineers with superior technical talents. With the collective knowledge and experience from our team of experts, we are capable of producing the next generation of protective face masks.

Guidelines We Follow

To comply with CE and FDA standards in terms of consumer and environment safety, we follow a strict QC process throughout the production process. The process consists of automatic and manual inspections, including a thorough probe of all raw materials. Our personnel will also perform hands-on analysis and sterilization of your orders before we ship them out.